La nostra Carpenteria in Alluminio

47030 Sogliano al Rubicone (FC)

P.Iva 03385310408

Aluminium Constructions: The Strength of Lightness

LAMEC di Ariano Davide . REA 298926 . SDI: M5UXCR1 . © 2026 All rights reserved

Aluminium sheet and tube processing

Passion and Quality since 2004

We have been operating in the metalworking industry for over 30 years

We specialise in aluminium carpentry construction

FROM DESIGN TO FINISHED PRODUCT

Specialised Team

Certified Quality

Tailor-made solutions and service

UNI EN ISO 3834-2

Ready to undertake every project with passion and professionalism

Our priority is to guarantee high-quality certified products

Personalised service,

expertise for customer needs

SERVICES AND PROCESSING

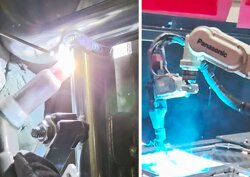

WELDING

TUBULAR PROCESSING

SHEET METAL WORKING

CUTTING AND CNC BENDING

TIG MIG ROBOTISED

LASER CUTTING CNC BENDING

For over 20 years, we have specialised in the production of sheet metal accessories and aluminium tubes for the aerial platform sector.

Baskets, gondolas, ladders, casings and various aluminium components.

We are partners with the most important leading manufacturers in the sector

CERTIFICATION

We operate in accordance with the standard

UNI EN ISO 3834-2

.png)

Certified Reliability

Welding Quality

Complete traceability

Welded products with superior quality to ensure greater safety and long life. Tested and certified procedures.

Detailed recording of each stage of the welding process for greater transparency and control.

Welding processes managed from design to execution and testing, with qualified welders and standard procedures.

PRODUCTION MANAGEMENT

Management software

Production Control

Each order is monitored in real time.

At the end of production, a report document is generated and archived, recording all the detailed information for each processing cycle involved.

Traceability and Quality Control

Our GP90 management system ensures the traceability of raw materials and processes used for each individual product.